A few weeks ago, Rhonda asked me if we could get a new clock for the living room. I got to wondering if maybe I could make one myself. We've got a new automated milling machine at work, and I figured I could make an old-fashioned clock with wooden gears. I decided to give it a try.

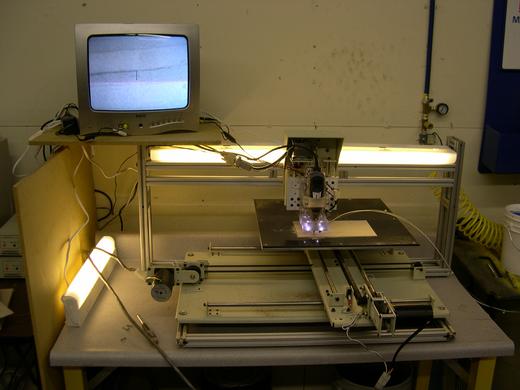

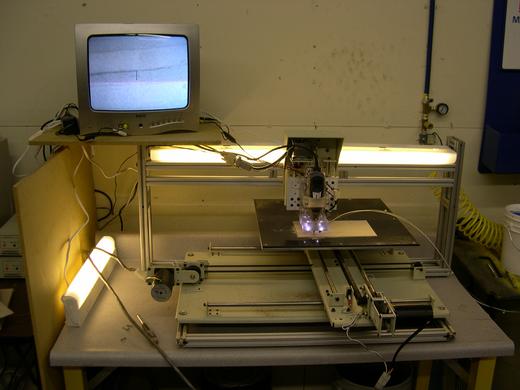

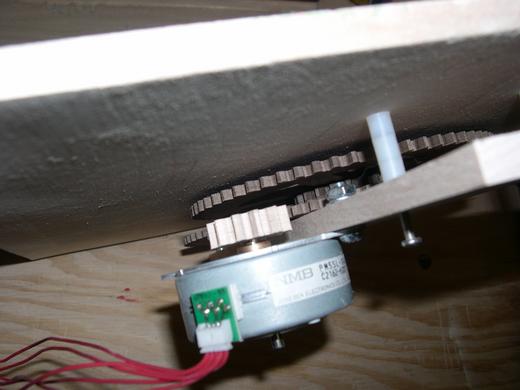

Here's the milling machine. It's really pretty simple. Three stepper motors control the X, Y and Z axes.

A Dremel tool is mounted with a screw drive to make it go up and down, and belts move the work surface in two

horizontal directions. An old PC controls the stepper motors. I wrote some software to control the system

by using Gerber files (normally used in the fabrication of printed circuit boards) to describe the tool movements.

This lets us use our existing PCB CAD software to design parts that can be cut on the milling machine.

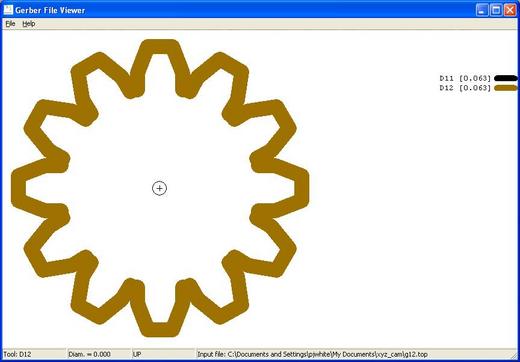

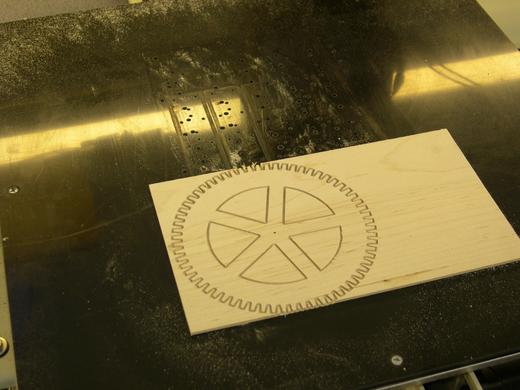

Designing a gear shape on the PCB CAD program would be incredibly tedious and difficult. So I wrote another program

that automatically creates a Gerber file for a gear shape, given gear diameter, number of teeth and number of spokes.

I also wrote a small Windows application to preview the Gerber files:

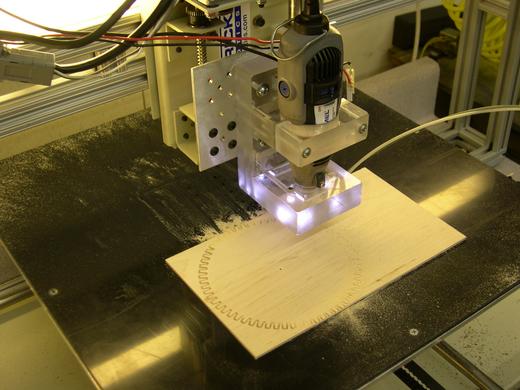

Here is the machine in action.

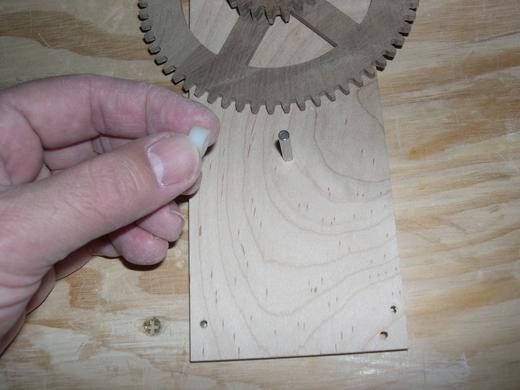

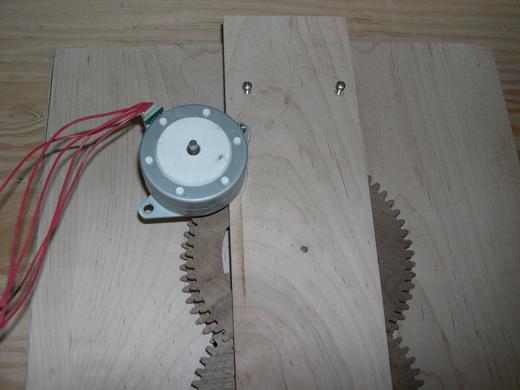

My clock design uses a total of four gears, including two compound gears (a small gear attached to a larger gear on a

common

axis). I could have added two more gears and included a second hand, but I wanted to keep things simple for this first

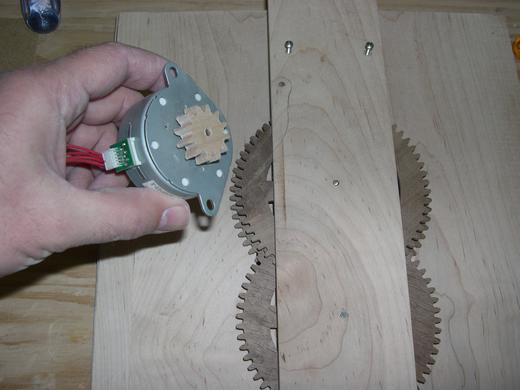

attempt. The "hour" gear has 64 teeth and a hollow axle that the hour hand will be mounted on.

The "idler" gear has a 16 tooth gear and a 60 tooth gear attached together with glue.

The "minute" gear is a compound gear has a 20 tooth gear and a 60 tooth gear and a solid axle that will hold

the minute hand.

The motive power comes from a stepper motor salvaged from an old ink-jet printer and a microprocessor that generates

step pulses once every minute to rotate the motor 1/12 of a revolution. With a 12 tooth gear on the motor, each movement

of the motor causes the minute hand to advance by 1/60 of a revolution. The gear ratios of 20:60 and 16:64 cause the hour

hand to follow along at 1/12 of a revolution every 60 minutes. Which is how a standard clock is supposed to work, if my

calculations are correct.

The face of the clock was made using the milling machine, also. I engraved the circular design and the numbers in a piece

of birch, and then inlaid them with walnut. The machine did a pretty good job of matching the inlays with the cutouts,

though I still had to do a bit of trimming and filling to make everything fit.

Here are more photos of the construction:

The clock hands were also designed on the PCB layout program and milled out of walnut. The axles are made from

steel rods salvaged from another old printer and brass tubing from the hobby shop. A few nylon washers are used to separate

the gears and get the spacing right.

Questions, comments to: Paul White.